PUMPS

FlowMAX TM Irrigation has two decades of expertise and experience in irrigation and water management and we have developed unique range of pumps which suites the special needs of the Irrigation industry. From the typical surface pumps to sophisticated Hydo pneumatic system with VFD, our flow and head ranges are selected to exactly matches the smallest needs of residential irrigation system to largest software parks and golf courses.Our dedicated team will examine the site conditions and design the head and discharge suitable for exact need of the system therby saving energy cost drastically with customized pumps.

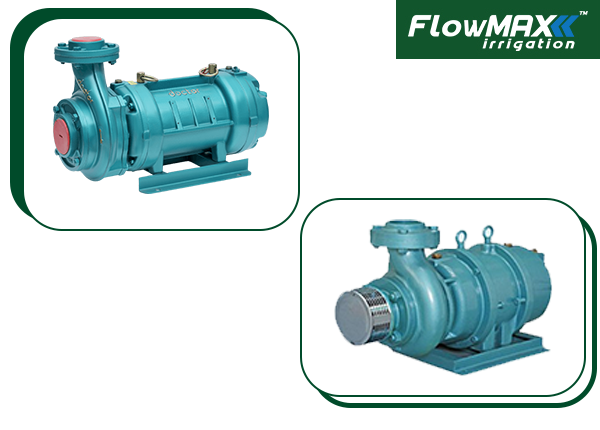

Centrifugal Monoblock Pumps

Centrifugal Monoblock Pumps

A Monoblock pump is a mechanical device wherein the motor as well as the pump is assembled jointly within a similar shelter. The shaft of the pump system includes revolving parts. A centrifugal monoblock pump as the name suggests functions on the basis of centrifugal force. It converts the energy provided by the motor to the energy within the liquid being pumped. Fresh water and fluids that are not chemically aggressive to pump components are recommended for centrifugal monoblock pumps.

FlowMAXTM centrifugal pumps comes in the range of 1 HP to 20 HP to meet the various needs of Irraigation requirment from small residence to bigger commerial landscape projects This pumps are energy efficient, easier to maintain and operrate at any type of water sources. All our pump ranges comes with one year service warranty.

Openwell submersible pumps

Openwell submersible pumps

FlowMAXTM Irrigation Openwell submersible pumps are our most efficient product for any irrigation system and they offer exceptional value and reliable performance.

As the name indicates, a submersible pump is designed to be submerged within the fluid being pumped. They are also known as Submersible water pumps or Openwell submersible pumps. They measure up against jet pumps as they are not subject to variations in elevation. They work underwater and rest at the bottom of the well. Jet pumps are prone to cavitation. Openwell submersible pumps use significantly less power, as the fluid they pump is pushed and not pulled.

The prime part of the pump, the motor is sealed with polymers, ‘O’rings, oil seals, and sand to prevent ingress of well water or salt into the motor. This feature helps in extending the durability of the submersible pump. The motor is prefilled with a cooler which regulates the temperature of the pump. A rubber diaphragm acts as a pressure equalizer and guards the motor against pressure and volume variation. The three-phase motor gives additional protection to all the electrical components.

Vertical Multistage Iinline Pumps

Vertical Multistage Iinline Pumps

A vertical multistage inline contains more than two impellers that are mounted on the same shaft. Through the inlet of the pump, the fluid flows into the eye of the impeller. The rotation motion of the impeller which is driven by an electric motor directs the fluid through the outer tip of the impeller vane and then enters the stage diffuser. The diffusers direct the fluid into the suction eye of the next impeller. This process continues for every impeller that the fluid passes through and finally into the pump discharge. At each stage, the discharge pressure increases.

FlowMAXTM Irrigation vertical Multistage pumps specially designed to suit the need of large commercial landscape areas, sports fields and big corporate farms. We will design the product specific to your site requirements and we can offer comprehensive maintenance for worry free ownership.

FlowMAXTM Irrigation Hydro Pneumatic System

FlowMAXTM Irrigation Hydro Pneumatic System

Hydro Pneumatic System are suitable for all kinds waters . The Products of the expertise gained from over decades of experience, endurance and workmanship . These products are experienced to perfection with utmost care and stringent quality control at all stages to ensure a trouble free service .

-

Features and Benefits:

- FlowMAXTM Irrigation Vertical multistage pump maximize performance, demonstrates high degree of consistency and is economical

- Pumps with VFD lasts longer as they can adjust the work load to meet the system requirement.

- Extremely quiet and low vibration when in operation. The smooth, automated start and stop, reduces water hammer.

- It avoids water pollution caused by roof tanks

- It also serves as the best replacement for the traditional roof tank water supply way, which is a source of water pollution.

- The VFD hydro pneumatic pumping systems are very specific use in Landscape Irrigation, it adjusts automatically the pressure and flow rate according the irrigation needs of the specific planting zone.

Gallery